Galvo Scanner for Laser Cutting: Take Full Advantage Of Efficiency and Precision

Galvo Scanner for Laser Cutting: Take Full Advantage Of Efficiency and Precision

Blog Article

A Comprehensive Guide to Various Kinds of Galvo Scanners and Their Applications

Galvo scanners, understood for their rate and precision, are essential to a range of markets from producing to medical technology. The journey to choosing the ideal galvo scanner for your operational requirements starts with comprehending these subtleties.

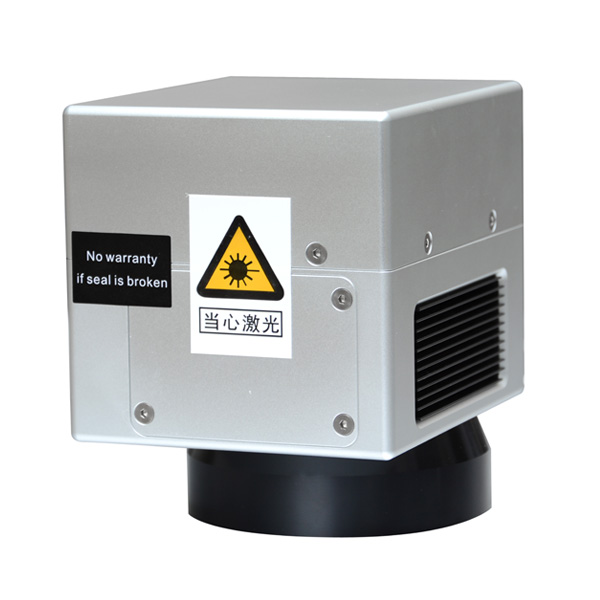

Basic Summary of Galvo Scanners

Galvo scanners, short for galvanometer scanners, are precision tools used to direct laser beam of lights properly and swiftly across a designated location. These gadgets play a crucial role in various markets, consisting of medical, production, and research study, by promoting high-speed and high-precision laser applications. Fundamentally, a galvo scanner includes a little, light-weight mirror connected to a galvanometer, which is an electromechanical device that measures electric existing by deflection of a needle. In this context, the galvanometer's deflection device relocates the mirror to guide the laser light beam.

The core principle behind galvo scanners is the exact and quick control of the mirror's angle, which consequently alters the direction of the laser beam of light. This is attained through a closed-loop comments system that makes sure the mirror's placement is continuously checked and readjusted for precision. The feedback system comprises placement sensing units, control electronics, and high-performance electric motors, supplying remarkable responsiveness and precision.

Galvo scanners master applications needing intricate and recurring laser motions, such as laser engraving, reducing, and clinical imaging. Their capability to run at high rates without giving up precision makes them essential in situations requiring both effectiveness and accuracy.

Kinds of Galvo Scanners

When discovering the types of galvo scanners, it's essential to recognize that variants are mainly based on their style, application requirements, and performance requirements. Normally, galvo scanners can be classified into single-axis and dual-axis designs.

Dual-axis galvo scanners, on the other hand, supply two-dimensional control of the light path. This makes them important in even more complicated applications like laser light programs, 3D printing, and clinical imaging. Dual-axis models are commonly equipped with 2 mirrors and equivalent galvanometers, permitting dynamic control over both X and Y works with.

Trick Functions to Take Into Consideration

When selecting a galvo scanner for your specific application,A number of vital functions should be diligently reviewed. Rate is a critical characteristic, as it determines the scanner's ability to deal with high-frequency jobs effectively. The speed is generally gauged in regards to action time and the maximum number of find out points per second the scanner can attend to.

An like it additional important function is the scanner's variety of motion, which indicates the maximum angular variance it can accomplish. A more comprehensive range gives better versatility but may call for a lot more innovative control systems. Thermal stability likewise needs focus, as temperature level changes can affect performance; therefore, choose scanners with robust thermal management systems.

Industry-Specific Applications

In numerous sectors, galvo scanners play an essential duty by boosting precision and performance in specialized applications. In the medical field, galvo scanners are integral to laser surgical procedures and sensory procedures, where high-speed, accurate beam positioning is vital. These devices make it possible for minimally invasive surgical procedures by specifically targeting tissue, therefore minimizing healing times and improving client results.

In production, galvo scanners are vital for laser inscription, reducing, and welding. Their capability to quickly and accurately direct laser beam of lights makes certain top notch coatings and detailed describing, which is crucial for the manufacturing of complicated components in auto, aerospace, and electronics markets. The fabric sector also takes advantage of galvo scanners in material cutting and inscription, supplying both speed and precision in handling diverse materials.

Selecting the Right Galvo Scanner

Picking the proper galvo scanner is a vital choice that rests on numerous vital factors, including application demands, efficiency specifications, and budget plan restraints. Initially, plainly specify the application requirements. Whether the scanner is intended for laser engraving, medical imaging, or 3D printing, each application requires specific performance characteristics such as resolution, speed, and accuracy.

2nd, take into consideration the efficiency specs. Specifications like check angle, reaction time, and thermal stability are essential (galvo scanner). A high-speed galvo scanner with a wide check angle is perfect for large-area noting, while applications needing great detail may prioritize high resolution and precision

Third, make up budget plan constraints. High-performance galvo scanners come with a considerable financial investment, however their lasting advantages can outweigh first costs. Examine the overall price of ownership, consisting of upkeep, to make sure the chosen scanner gives value over its life expectancy.

Final Thought

Recognizing the diverse sorts of galvo scanners and their special capacities is critical for optimizing efficiency across different sectors. Dual-axis and single-axis versions satisfy different operational intricacies, while high-speed and high-precision variations attend to particular demands in production, fabrics, medical fields, and 3D printing. Careful choice based on the one-of-a-kind functions and application needs of each sort of galvo scanner ensures improved performance and precision, thus dramatically enhancing general functional outcomes.

Galvo scanners, brief for galvanometer scanners, are accuracy tools used to guide laser light beams accurately and quickly across an assigned location.When exploring the types of galvo scanners, it's critical to understand that variations are primarily based on their style, application demands, and efficiency requirements. Each type of galvo scanner is thus distinctly tailored to meet specific operational demands, making certain optimal performance throughout numerous applications.

The accuracy of a galvo scanner directly impacts the high quality of the output, making it necessary to think about the scanner's capability to keep high-resolution efficiency (galvo scanner). Cautious selection based on the distinct attributes and application requirements of each kind of galvo scanner ensures improved effectiveness and Resources precision, thereby significantly boosting general operational results

Report this page